Titanium Grade 23 Round Bars from Nevio Steel India represent the pinnacle of high-performance titanium alloys, engineered to meet the most demanding industrial and medical applications. Known under the UNS R56403 designation and conforming to the ASTM B348 standard, these round bars combine exceptional strength, lightweight properties, and outstanding corrosion resistance. As a premium Titanium Alloy Round Bars Manufacturers, Suppliers, Stockists, and Exporters, Nevio Steel India ensures that each bar is precisely manufactured to provide consistent mechanical and chemical properties suitable for aerospace, medical implants, chemical processing, marine, and automotive industries.

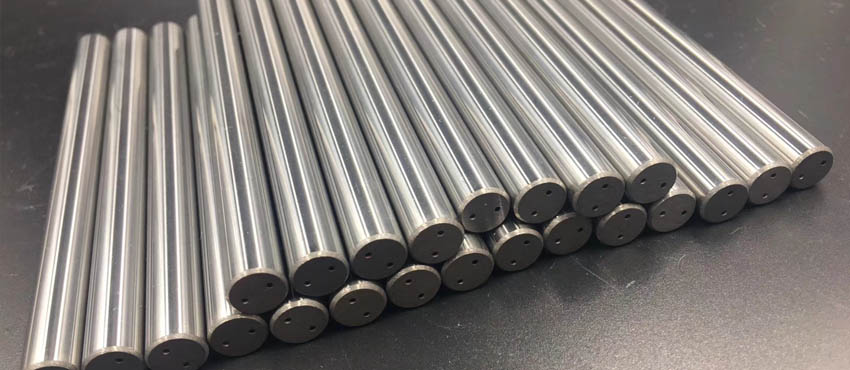

The Titanium Grade 23, also known as Ti-6Al-4V ELI (Extra Low Interstitial), is a refined version of Grade 5 titanium, offering superior fracture toughness and biocompatibility. Its low interstitial levels of oxygen, carbon, nitrogen, and iron enhance ductility and fatigue resistance, making it the preferred choice for critical applications such as surgical implants, aircraft components, and high-performance racing parts. Nevio Steel India’s round bars are meticulously processed using advanced forging and extrusion techniques, ensuring uniform microstructure and excellent surface finish suitable for precision machining.

Our Titanium Grade 23 Round Bars Suppliers focus on delivering products that meet international quality standards. Each batch undergoes rigorous testing including tensile, hardness, and chemical composition analysis to ensure compliance with ASTM B348 and UNS R56403 specifications. The superior corrosion resistance of Grade 23 makes it ideal for marine and chemical environments, while its high strength-to-weight ratio benefits aerospace structures where weight reduction without compromising performance is critical.

Available in various diameters and lengths, Titanium Grade 23 Round Bars Exporters provide flexible solutions to meet specific project requirements. Nevio Steel India ensures ready stock availability to support timely project execution for clients worldwide. The material’s excellent weldability, machinability, and fatigue resistance make it versatile for components ranging from orthopedic implants to high-performance engineering applications.

For industries seeking a reliable supplier, Nevio Steel India is recognized as one of the leading Titanium Grade 23 Round Bars Manufacturers in Mumbai, India. With a commitment to quality, timely delivery, and technical support, we empower clients to achieve precision engineering goals efficiently. Partnering with us guarantees access to world-class titanium round bars that adhere to ASTM B348, UNS R56403, and global quality benchmarks.

Our Titanium Grade 23 Round Bars are synonymous with excellence, offering a combination of lightweight design, high mechanical strength, and superior corrosion resistance. Nevio Steel India continues to serve industries that demand the highest standards of titanium alloy products with global shipping capabilities, making us a preferred Stockists and Exporters of Titanium Grade 23 worldwide.

| Dimension : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

|---|---|

| Standard : | ASTM B265, ASTM B337, ASTM B338, ASTM B348, ASTM 367, ASTM B381, ASTM F67, ASTM B467, ASTM B468, ASME SB-348 |

| Size : | Dia6.0-200mm x Length1000-6000mm |

| Tolerance : | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Form : | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Form : | Round, Square, Rectangular, Hydraulic Etc |

| Length : | Single Random, Double Random & Required Length, Custom Size – 12 Meter lengths |

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Titanium Grade 23 | 3.7165 | R56407 |

| Grade | C | N | O | H | V | AI | Fe |

|---|---|---|---|---|---|---|---|

| Titanium Gr 23 | 0.08 max | 0.03 max | 0.13 max | 0.0125 max | 3.5 - 4.5 | 5.5 - 6.5 | 0.25 max |

| Density | Melting range | Tensile strength, min | Yield strength, 0.2% offset, min, Mpa | Elongation at Break, % | Hardness, Rockwell B |

|---|---|---|---|---|---|

| 4.43 g/cc | Max 1650 °C | 860 MPa | 790 MPa | 10 | 30-35 |