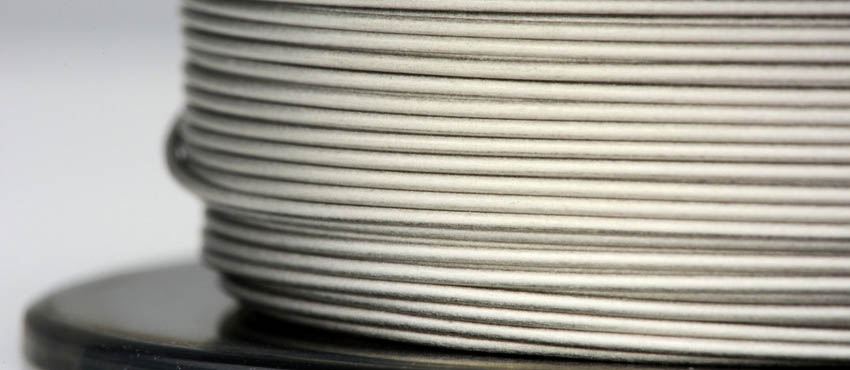

Titanium Gr 5 Wires offered by Nevio Steel India are engineered to deliver exceptional strength, corrosion resistance, and biocompatibility, making them ideal for aerospace, medical, marine, and chemical processing applications. Manufactured in compliance with ASTM B863/B348 Grade 5 and UNS R56400 standards, these wires ensure reliable performance in demanding environments. Titanium Gr 5 Wires feature a high tensile strength combined with excellent fatigue resistance, making them perfect for applications requiring durability under stress while maintaining lightweight properties.

The superior corrosion resistance of Titanium Gr 5 Wires protects against oxidation and chemical attack, even in harsh environments such as saltwater exposure and acidic atmospheres. Their excellent mechanical properties, including high strength-to-weight ratio, make these wires suitable for critical aerospace components, surgical instruments, implants, and high-performance industrial equipment. Nevio Steel India ensures that every wire is carefully manufactured to meet stringent quality standards, providing consistent diameter, surface finish, and chemical composition.

Available in various diameters and lengths, Titanium Gr 5 Wires can be customized to meet specific industrial and medical requirements. These wires are used extensively in aerospace applications for aircraft components, engine parts, and structural assemblies due to their ability to withstand extreme temperatures and stress. In the medical field, Titanium Gr 5 Wires are highly valued for surgical implants, orthopedic devices, and dental instruments due to their biocompatibility and non-reactive nature.

Nevio Steel India has established itself as a leading Titanium Gr 5 Wires Manufacturer, Supplier, Stockist, and Exporter in Mumbai, India. With advanced production facilities, strict quality control, and adherence to international standards, the company ensures that all products meet the highest standards of performance and reliability. Their commitment to excellence makes them a preferred choice for global clients seeking high-quality titanium wires for precision applications.

These wires conform to universal specifications including ASTM B863/B348, ensuring compatibility with international engineering and medical standards. With high strength, low density, and excellent corrosion resistance, Titanium Gr 5 Wires are indispensable in industries where material reliability is critical. Clients can rely on Nevio Steel India for timely supply, customization options, and technical support for all their titanium wire requirements.

For customers worldwide, Nevio Steel India provides Titanium Gr 5 Wires that guarantee exceptional durability, precision, and safety. Whether for aerospace, medical, chemical, or marine applications, these wires offer consistent quality and performance, making them an ideal choice for industries that demand the best. Trust Nevio Steel India for high-quality titanium solutions tailored to your specific application needs.

| Specification : | ASTM B863 ASME SB863 |

|---|---|

| Dimensions | ANSI/AWCI – 01 -1992 and ASTM E 2016-11 and RRW 360 |

| Size | 1/16”OD to 2”OD, 2mm OD to 50mm OD |

| Diameter | 10 mm To 100 mm |

| Diameter | 10 mm To 100 mm |

| Inspection, Test Reports : | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing : | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials : | Filler Wire, Coil Wire, Electrode Wire, Welding Wire. |

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Titanium Gr 5 | 3.7165 | R56400 |

| Grade | C | N | O | H | Ti | Fe | V | Al |

|---|---|---|---|---|---|---|---|---|

| Titanium Gr 5 | 0.10 max | 0.05 max | 0.20 max | 0.015 max | bal | 0.30 max | 3.5-4.5 | 5.5-6.75 max |

| Min.Tensile(KSI) | Min.Yield(KSI) | Hardness | Tensile Modulus | Poisson's Ratio |

|---|---|---|---|---|

| 130 | 120 | 16.4 | 114 GPa | 0.30-0.33 |